Extend the lifespan of your LEV system with predictive maintenance

Katie Burrell, P602-qualified project engineer at APS | Published February 18th 2026 | Updated February 18th 2026

Are unplanned LEV system breakdowns leading to costly production stoppages? In our latest blog, our Project Engineer Katie Burrell talks through how you can extend the lifespan of your LEV system by implementing predictive maintenance.

How does predictive maintenance work alongside your dust extraction equipment?

With good care and regular maintenance, your dust extraction equipment should last for years. If, however, you’re seeing frequent unplanned breakdowns, it may be 1) time to get an engineer in, and 2) time to look at implementing predictive maintenance.

In its simplest form, predictive maintenance uses real-time sensors to monitor key equipment, like dust collectors, to flag issues like overheating or excessive vibration and allow maintenance to take place before they spiral into bigger problems.

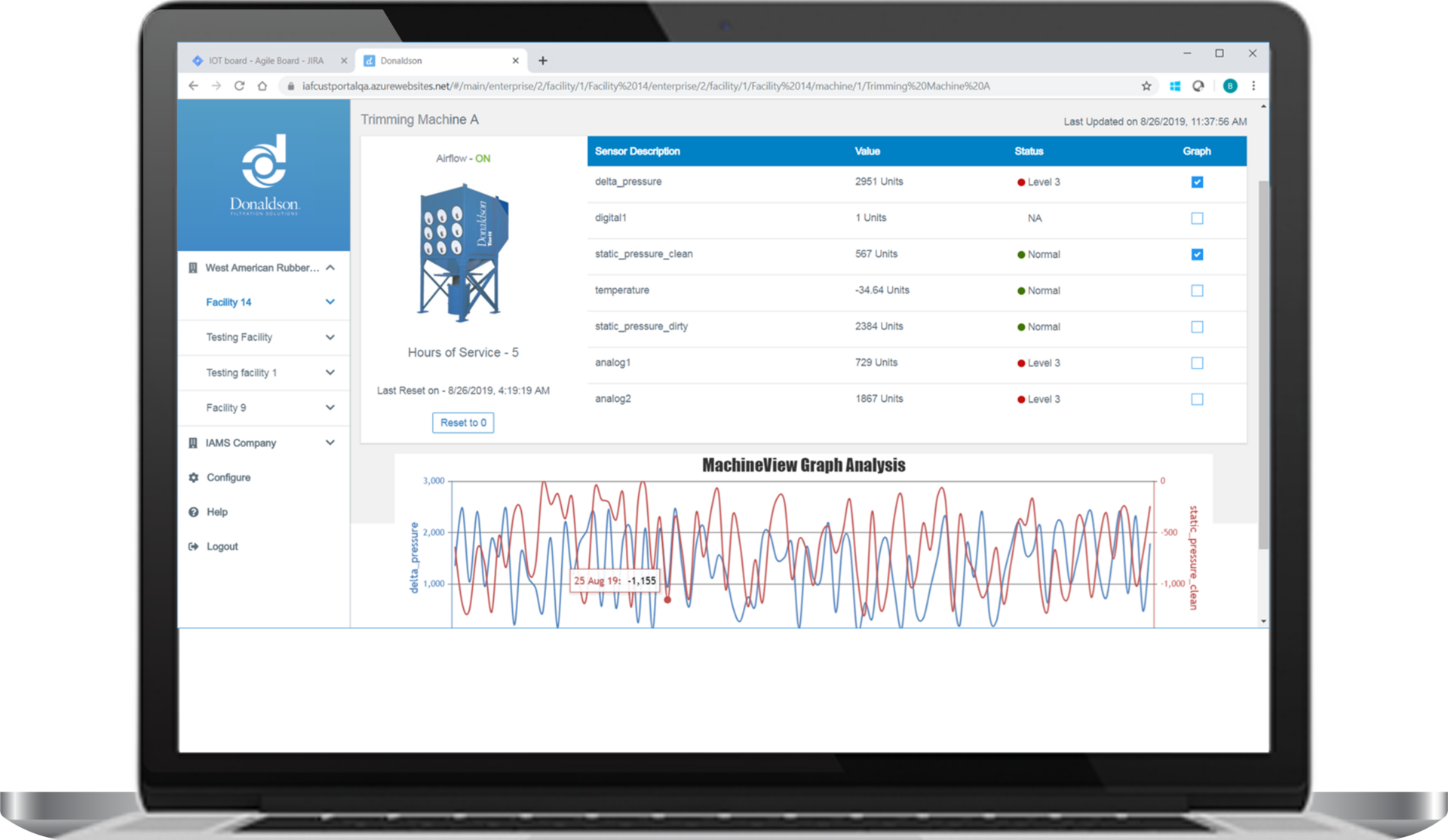

On a dust extractor, software like Donaldson’s iCue™ Connected Filtration Services is used to remotely monitor equipment to provide operational insights. This includes monitoring the airflow, fan energy and power, particulate trends, internal temperature, and differential pressure, alongside flagging issues like imminent dust overflow.

As a Donaldson partner, here at APS we’re well versed in installing predictive maintenance software on existing dust collection equipment, and our engineering team can help you go from a reactive, fix-it-when-it-fails approach, to a proactive maintenance strategy that lowers operational costs.

What are the benefits of predictive maintenance in dust extraction?

Benefits of predictive maintenance in dust extraction include:

By implementing predictive maintenance, you can detect issues like low airflow, filter leaks, and end of filter life early, helping free up your maintenance team.

How you can maintain your dust extractor with predictive maintenance

Regular maintenance of your dust collector is essential to keep it functioning as it should be – an LEV system should be tested every 14 months, and serviced at least once a year, or more in high usage environments.

Predictive maintenance software can form a key part of your maintenance schedule, stopping you from relying on fixed intervals for servicing, and instead moving you to a model where maintenance is based on the real-time condition of the equipment.

This means servicing can be scheduled during planned downtime periods or non-peak production hours, preventing costly and unexpected disruptions to production.

At APS, we offer a comprehensive aftercare service, that will keep your dust extraction system operating optimally, reducing downtime and maximising the cost-effectiveness of maintenance. Every new Donaldson dust collector installed comes with the predictive maintenance software iCue™ Connected Filtration Services as standard. We can also implement the software on any existing dust extraction equipment.

Once implemented, you’ll have access to a dashboard where you can view each of your LEV systems, and see near real-time data as well as historical trend data. You’ll receive alarms and notifications when maintenance actions may be required, and custom reports summarising performance.

Not confident monitoring your dust extractor yourself? Our expert engineers at APS can also monitor equipment on your behalf, and let you know when maintenance needs to take place.

Ready to reduce downtime on your factory floor?

Get your production on track by speaking to our expert team today, and we’ll discuss how to implement predictive maintenance on your dust collection equipment.

Predictive maintenance FAQs

A: Predictive maintenance is a maintenance strategy that uses real-time data from sensors alongside AI analytics to predict when industrial equipment is likely to fail.

A: In dust extraction, predictive maintenance works by using sensors attached to equipment to continuously monitor key equipment performance parameters, like filter condition in real-time to forecast potential failures before they cause downtime.

A: Predictive maintenance offers numerous benefits, in reducing unplanned downtime, lowering maintenance costs, extending the service life of equipment, and ensuring workplace safety.

Yes. As a Donaldson distributor, APS can implement the predictive maintenance software iCue™ Connected Filtration Services on any dust extraction equipment. Our expert engineers can also monitor equipment on your behalf, and let you know when maintenance needs to take place.

We Consult

Understanding is key. We take the time to grasp your specific requirements, ensuring solutions tailored just for you.

We Design

With your needs as our blueprint, we craft designs that are both functional and in step with modern aesthetics.

We Install

Our team prioritises a smooth, efficient installation process, minimising disruption while focusing on optimal safety outcomes.