Predictive Maintenance in Dust Extraction

If unplanned LEV system breakdowns are leading to costly production stoppages on your line, you might want to look at implementing predictive maintenance. Through software like Donaldson’s iCue™ Connected Filtration Services, you can monitor your facility’s dust collection equipment and see key insights into its performance.

Ready to reduce downtime?

Maximise your productivity and monitor your filtration performance with real-time equipment data and maintenance alerts.

What is predictive maintenance in dust extraction?

Predictive maintenance uses real-time sensors to monitor key equipment, like dust collectors, to flag issues like overheating or excessive vibration.

It allows maintenance to take place before small issues spiral into bigger problems, taking engineering teams from a reactive, fix-it-when-it-fails approach to a proactive maintenance strategy that lowers operational costs.

What are the benefits of predictive maintenance?

Benefits of predictive maintenance in dust extraction include:

Predictive maintenance services from APS

Donaldson’s software, iCue™ Connected Filtration Services, comes as standard on every Donaldson dust collector installed.

As a Donaldson distributor, we can retrofit iCue™ Connected Filtration Services on any existing equipment too.

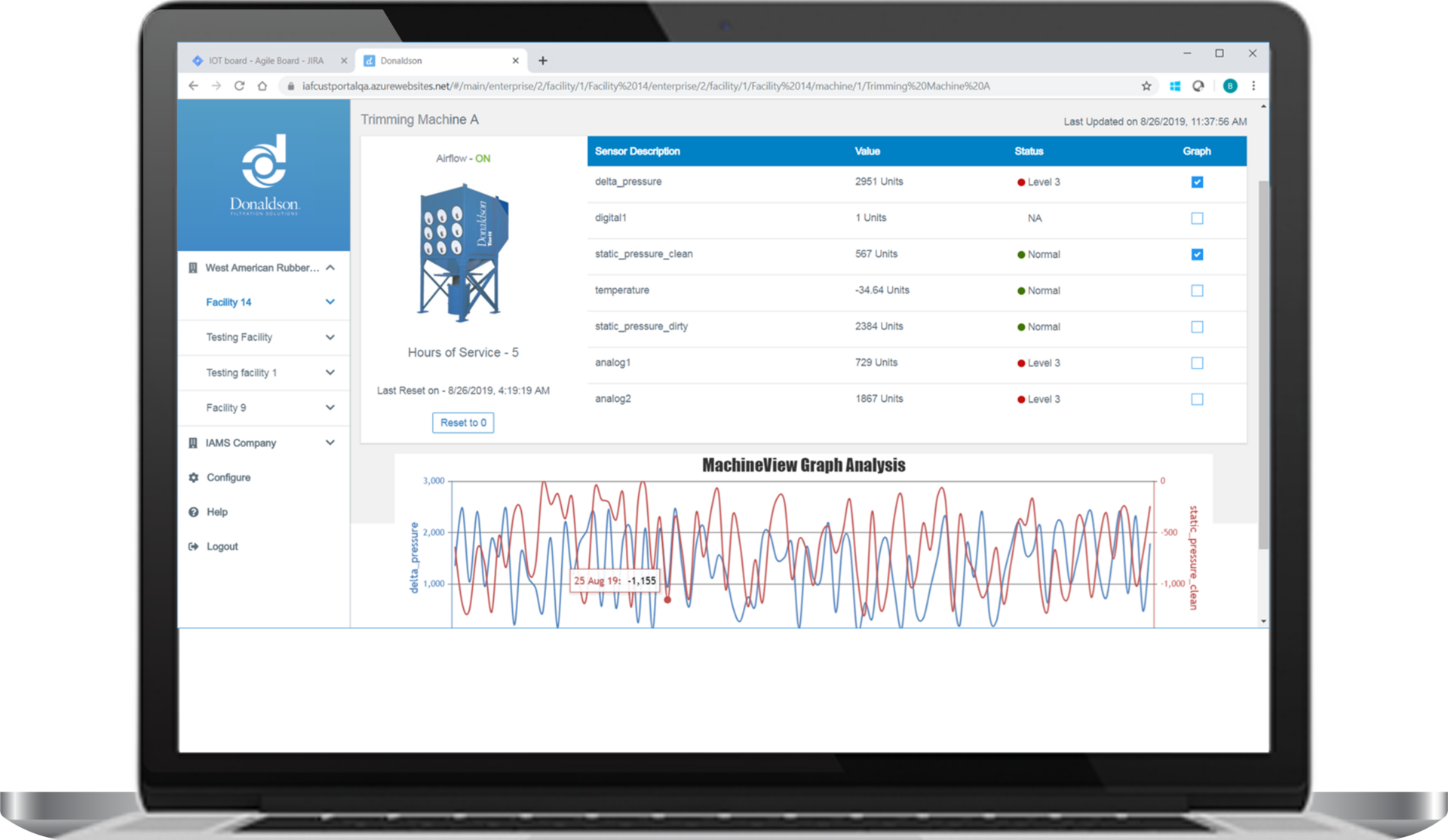

The iCue™ software monitors industrial dust and fume collectors through sensors attached to the equipment. It looks at airflow, fan energy and power, particulate trends, internal temperature, and differential pressure, alongside flagging issues like imminent dust overflow.

Once implemented, you’ll have access to a dashboard where you can view each of your LEV systems, and see near real-time data as well as historical trend data. You’ll receive alarms and notifications when maintenance actions may be required, and custom reports summarising performance.

Our expert engineers at APS can monitor equipment on your behalf, and let you know when maintenance needs to take place.

Get in touch

Ready to eliminate your downtime worries? Get in touch with our team to learn more about predictive maintenance.

Predictive Maintenance FAQs

A: Predictive maintenance is a maintenance strategy that uses real-time data from sensors alongside AI analytics to predict when industrial equipment is likely to fail.

A: In dust extraction, predictive maintenance works by using sensors attached to equipment to continuously monitor key equipment performance parameters, like vibration, in real-time to forecast potential failures before they cause downtime.

A: Predictive maintenance offers numerous benefits, in reducing unplanned downtime, lowering maintenance costs, extending the service life of equipment, and ensuring workplace safety.

A: Yes. As a Donaldson distributor, APS can implement the predictive maintenance software iCue™ Connected Filtration Services on any dust extraction equipment. Our expert engineers can also monitor equipment on your behalf, and let you know when maintenance needs to take place.