Importance of LEV Systems and Testing

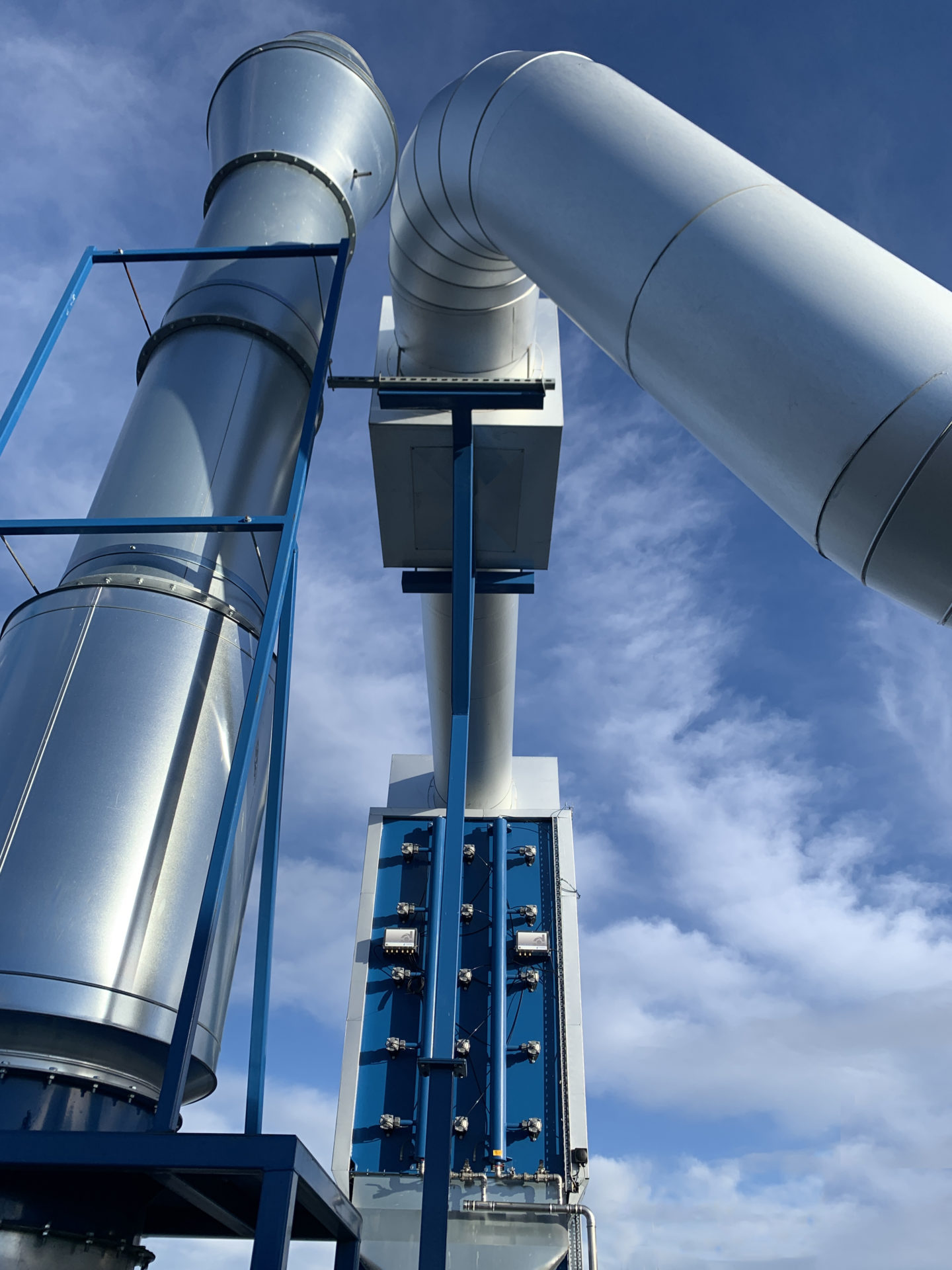

With over 50 years of experience in the airbourne contaminant control industry, APS UK is a trusted expert in providing comprehensive solutions for dust and fume LEV (Local Exhaust Ventilation) systems.

Our team of engineers excels in this field, and we take pride in delivering exceptional service that exceeds industry standards, as set by the Health & Safety Executive (HSE), the British Occupational Hygiene Society and other industry bodies.

In the UK, it is alarming to note that there are between 12,000 and 13,000 deaths annually due to prolonged exposure to airborne contaminants in the workplace. At APS UK, we recognise the severity of this issue, which is why we emphasise the importance of good LEV design. We urge companies that generate excessive amounts of dust, mist, fumes, and gases to seriously consider implementing the installation of good LEV systems as a vital part of their safety protocols.

LEV (Local Exhaust Ventilation) systems are designed to minimise the risk of exposure, for workers/operators/visitors, to harmful airborne substances in the workplace.

In the UK alone, there are approximately 140,000 LEV systems, making them an integral component of a company’s risk control strategy to protect employees and mitigate health-related problems within the workplace, however much more still needs to be done to reduce the overall exposure for many people in work today.

How does LEV testing work?

One crucial aspect of our service is LEV Testing, which plays a significant role in ensuring the safety and well-being of workers in environments where airborne contaminants are present.

Through LEV testing, employers can ensure that the control measures they have in place to safeguard their workforce, and prevent work-related health issues, are appropriate and functioning correctly.

It is a process that verifies the proper functioning of workplace machinery, ensuring compliance with industry standards and Health and Safety Executive (HSE) guidelines. Our expert team evaluates the design, manufacturer’s guidelines, and any previous testing or maintenance records. Subsequently, we assess the Quantitive and Qualatitive performance of a LEV system by measuring airflow rates, air velocity, and pressure differentials at various points within the system.

If any deficiencies or issues are identified during the testing, we provide recommendations for adjustments or improvements. This may involve modifying airflow rates, replacing filters, repairing system components, or implementing additional control measures to enhance the efficiency and effectiveness of the LEV system.

At APS UK, we adhere to the COSHH Regulations and HSE Guidance, conducting comprehensive examinations and testing of ventilation systems. We offer a tailored approach to our services, accommodating your specific needs. Whether you require a combined service and test or individual assessments, we are here to assist you.

Here are some important statistics that highlight the urgency of addressing workplace hazards:

• Over 7,000 deaths occur each year due to occupational respiratory cancer, which is thirty times higher than the number of deaths resulting from industrial accidents.

• There are approximately 140,000 LEV systems in the UK.

• Only 40% of these systems are tested annually, meaning that 60% of them go uninspected.

• A significant portion of the 40% tested are not adequately checked for effectiveness.

• Only 500,000 individuals rely on LEV systems to protect their health out of a manufacturing industry working population of approx. 5,600,000

If your workplace requires a new LEV System and or operates large-scale LEV systems and requires our services, please don’t hesitate to contact our friendly team at 01904 215101 or via email at sales@apsukltd.co.uk. We are committed to helping you create a safer and healthier work environment through the implementation of effective LEV testing and dust extraction solutions.

We Consult

Understanding is key. We take the time to grasp your specific requirements, ensuring solutions tailored just for you.

We Design

With your needs as our blueprint, we craft designs that are both functional and in step with modern aesthetics.

We Install

Our team prioritises a smooth, efficient installation process, minimising disruption while focusing on optimal safety outcomes.