The Five Biggest Dangers of Dust in the Workplace: How You Can Control Them

Matt Brown | Published November 21st 2024 | Updated October 6th 2025

Dust in the workplace can be a dangerous and costly problem for businesses, disrupting production and damaging the health of your workforce.

Dust in the workplace can be a dangerous and costly problem for businesses. Not only can it infiltrate sensitive machinery and cause lengthy downtimes, but it can also seriously damage the health of employees, leading to long-term problems.

It’s therefore important to implement methods of dust control in the workplace, including through the installation of Local Exhaust Ventilation (LEV) extraction systems.

What counts as hazardous dust?

All airborne dust is hazardous to health. Any exposure can be dangerous, with the potential of health issues for employees, cross contamination, and a risk of fires and explosions.

Different industries generate different dust. Food manufacturers handle ingredients such as sugar, instant coffee, fine spices and flour, while pharmaceutical production facilities generate potentially toxic dust from processes such as crushing, mixing and blending.

What are the dangers of dust in the workplace?

The presence of dust in the workplace can cause multiple issues, for employees, potential customers, and the business as a whole.

Cross-contamination

A significant issue in the food and pharmaceutical industries, cross-contamination occurs when unwanted particles come into contact with the food or medicines during the production or packaging process.

In these industries, compliance with safety regulations is paramount, to eliminate health risks for consumers. Clean air can prevent contamination, and the installation of Local Exhaust Ventilation (LEV) extraction systems is essential in helping to control airborne dust.

Damage to machinery

Fine dust particles can affect machinery, causing clogs and malfunctions, and accelerating wear on moving parts such as bearings and gears. This can lead to costly repairs, downtime, and a reduced lifespan of equipment, meaning operations are disrupted.

It’s important to ensure proper cleaning processes are in place to reduce the risk of dust damaging machinery. Dust extraction systems can remove the risk at source, allowing your production processes to stay up and running for as long as possible.

Irritation and allergic reactions

Some dusts, including wood dust, fibreglass, and epoxy resin can cause skin ulceration and irritation, and can cause eye damage too.

Airborne dust can also present risks for those with allergies, and extended exposure to dust on the skin can cause itchiness, dryness, and scaling.

To reduce the hazards faced by employees, dust should be controlled at its source. Experienced companies like APS can help you identify a method of dust extraction that works for your business, using years of expertise from working with various industries.

Permanent respiratory damage

The inhalation and overexposure to dust can cause breathing problems, that could eventually lead to life-threatening respiratory diseases.

Certain types of dust, such as flour dust, trigger coughing and wheezing attacks, and can cause occupational asthma. Other types of hazardous dust, including silica dust, can lead to cancer, potentially proving fatal.

The Control of Substances Hazardous to Health (COSHH) regulations require employers to adequately control exposure to materials in the workplace that cause ill health. By installing a high-quality LEV extraction system, you can ensure compliance with these regulations, and therefore ensure the safety of your employees.

Fires and explosions

Various industries, including food processing, generate combustible dust, which can trigger fires and explosions, and cause serious harm to employees and businesses.

Dangerous Substances and Explosive Atmospheres Regulations (DSEAR) 2002 require employers to find out what dangerous substances are in their workplace and what the risks are, and put measures in place to control or remove those risks.

Installing dust extraction systems removes combustible dust from the working environment, minimising the potential of fires and explosions.

How do you control dust in the workplace?

Under the Management of Health and Safety at Work Regulations 1999, employers should identify hazards, assess their risks, and put methods in place to control those hazards.

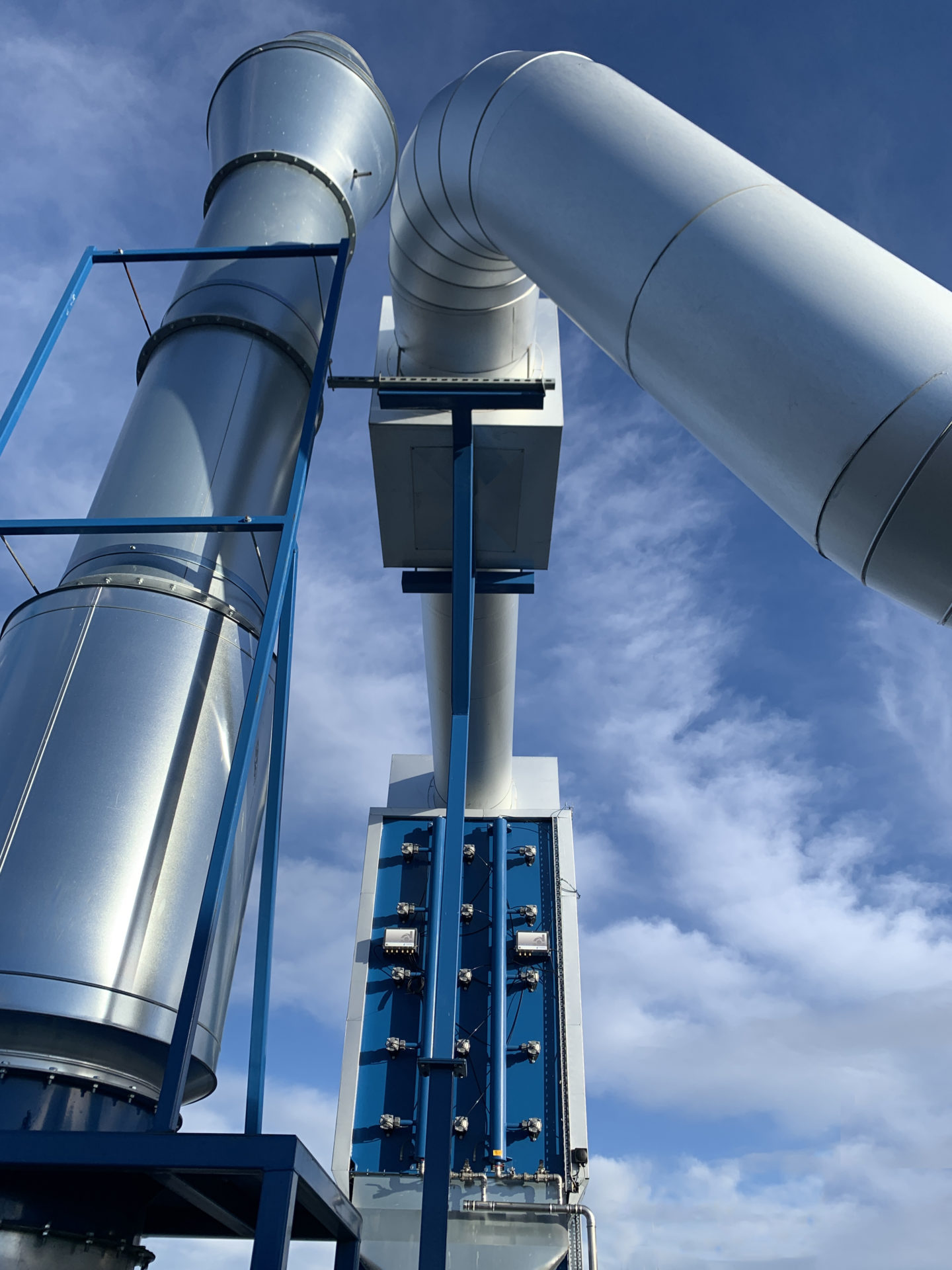

LEV extraction systems are essential in controlling airborne dust and fume particles. When properly designed, installed and maintained, a high-quality LEV extraction system will remove contaminants at source, and capture them in a specially designed replaceable filter mechanism.

Here at APS, our expert engineers will work with you to advise on installations and upgrades, helping you keep your employees and your business safe. With vast experience in dust extraction across various industries, we offer bespoke systems, with a comprehensive range of filter solutions to suit all needs.

We recently provided a dust extraction system for a leading confectionery manufacturer, which needed to reduce the build-up of airborne sugar dust on machines.

After installation, operatives experienced a significant reduction in airborne dust levels in their working areas, creating a healthier work environment. The build-up of dust on machines was also substantially reduced, having a positive impact on quality.

For assistance in making sure your business meets COSHH regulations and DSEAR, get in touch with us today.

We Consult

Understanding is key. We take the time to grasp your specific requirements, ensuring solutions tailored just for you.

We Design

With your needs as our blueprint, we craft designs that are both functional and in step with modern aesthetics.

We Install

Our team prioritises a smooth, efficient installation process, minimising disruption while focusing on optimal safety outcomes.