Front-End Engineering Design (FEED) services for industrial dust extraction

Want to safeguard your employees from harmful production dust? A high-quality, well-designed dust extraction system, developed using Front-End Engineering Design (FEED) principles shields your team from both short and long-term health risks, as well as supporting consistent product quality and regulatory compliance.

The effectiveness of any LEV starts long before installation. It begins with smart, bespoke design tailored to your needs as a customer.

This is where a APS Front-End Engineering Design (FEED) study comes in.

What is Front-End Engineering Design, and how is it used in dust extraction?

Front-End Engineering Design, also known as FEED, is a crucial engineering design phase, and at APS, it’s where we bridge the gap between conceptualisation and execution.

Here, our qualified designers and engineers:

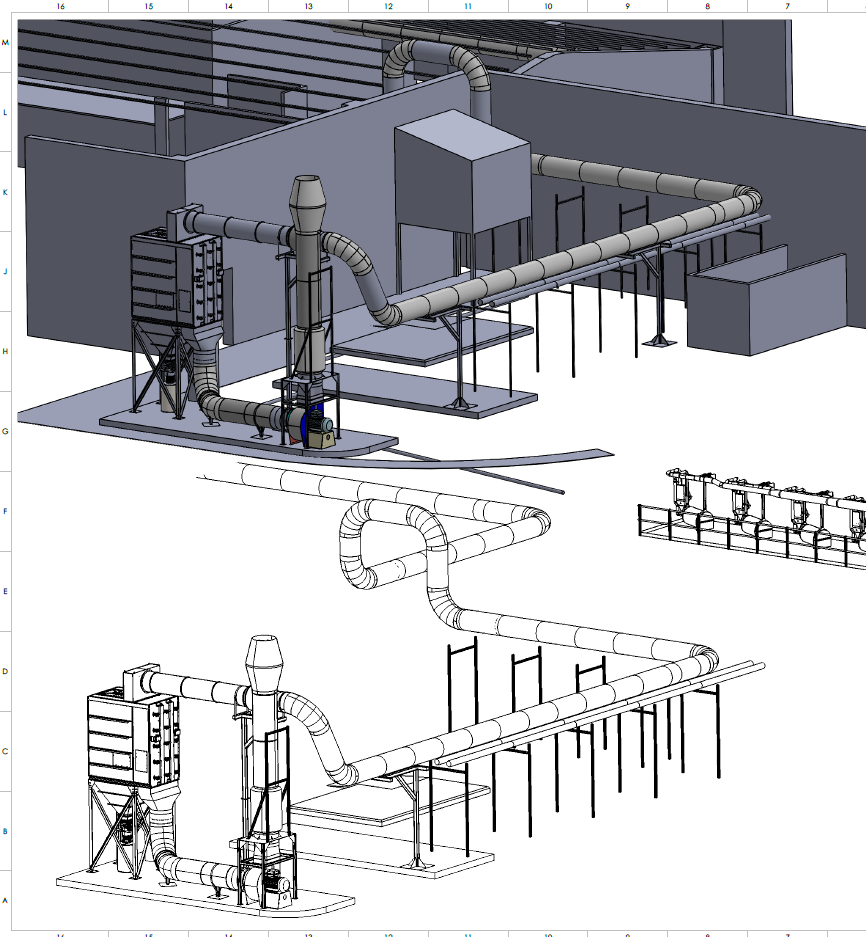

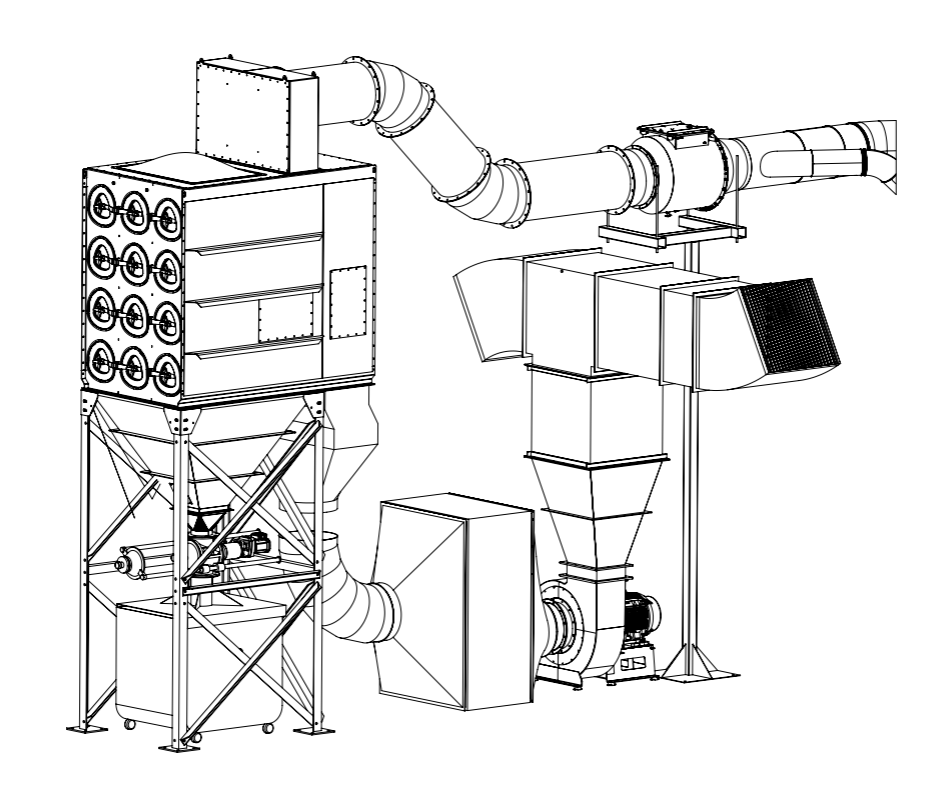

We use FEED to develop detailed plans for effective Local Exhaust Ventilation (LEV) systems. The aim of FEED is to:

It gives you a detailed framework for decision-making, determines a project’s feasibility and gives an accurate cost estimate before a full investment is made.

To summarise: it helps you make sure you’re making the right decision.

How does FEED work?

So, you’ve decided you need a new LEV dust extraction system. But where do you start?

Any extraction project that involves external parties needs clear, detailed accurate information from the outset. Without it, assumptions creep in, and you end up with a standard solution that fits your chosen supplier, not you.

With APS, you’ll go through a collaborative process with our engineers to bring you the best end solution for your LEV extraction needs.

You tell us your requirements, we assess your site and processes, and our P602 certificated designers will create a document detailing everything your dust extraction partner – or ourselves – should be considering for your new system.

A FEED study will, in detail:

Why Front-End Engineering Design is important for LEV and dust extraction

In LEV and dust extraction, FEED ensures that a system effectively and efficiently captures and removes dust at source.

A good system design maximises effective dust control by considering:

Why using FEED sets you up for success

FEED ensures your dust extraction system is designed correctly from the outset, delivering key benefits such as:

Why you should opt for FEED

“If you want a dust extraction system that’s safe, compliant, and built to last, start with FEED. Choosing the FEED process helps you avoid guesswork, ensuring your system is designed right the first time.

“It turns often highly complex projects into clear, informed decision-making frameworks, giving you accurate costs and design expectations so you don’t face any surprises along the way.

“Opting for FEED, means opting for peace of mind.”

Katie Burrell

P602-qualified Project Engineer at APS

Want a smarter dust extraction system? Get in touch

Avoid guesswork on major dust and fume projects with a FEED study.

If you need a dust extraction system that’s safe, compliant, and built to last, speak to our team about FEED today.

Front-End Engineering Design (FEED) FAQs

A: Front-End Engineering Design, also known as FEED, is a crucial engineering design phase where we the gap is bridged between conceptualisation and execution of a dust extraction project.

A: It gives you as a customer a detailed framework for decision-making, and develops a detailed plan for an effective Local Exhaust Ventilation (LEV) system that protects your operational staff from harmful dust, and safeguards your processing equipment.

A: If you opt to go down the FEED route here with APS, you’ll go through a collaborative process with our engineers focused on bringing

you the best end solution for your LEV extraction needs. You’ll tell us your expectations, we’ll assess your site and processes, and our P602 certificated designers will create a sizable document detailing everything your dust extraction partner – or ourselves – should be

considering when implementing your new system.

A: A FEED study is a foundational project roadmap from initial risk assessments through to the timelines for full system implementation, and will include:

requirements and configuratio

and ATEX

generation

A: FEED ensures that a system is effective and efficient in capturing and removing dust at source, helping you ensure your operational team and production line is safeguarded from harmful airborne particles.

A: FEED helps ensure your dust extraction system is designed correctly from the start, giving you key benefits such as:

A: Choosing the FEED process helps you avoid guesswork, ensuring your system is designed right the first time. It turns highly complex projects into informed decision-making frameworks, giving you accurate costs and design expectations so you don’t face any surprises along the way. In short, opting for FEED, means opting for peace of mind.