How Pneumatic Conveying Optimises Recycling Processes

Author: Adrian Ogden

Published: 20/11/2023

– Pneumatic conveying is transforming recycling by swiftly transporting materials through air pressure, overcoming challenges and enhancing efficiency.

– Pneumatic conveying systems bring efficiency, flexibility, and contamination reduction to recycling, preserving material quality and cutting labour costs.

– APS, an industry expert, tailors pneumatic conveying solutions for recycling, optimising material transportation for various recyclables.

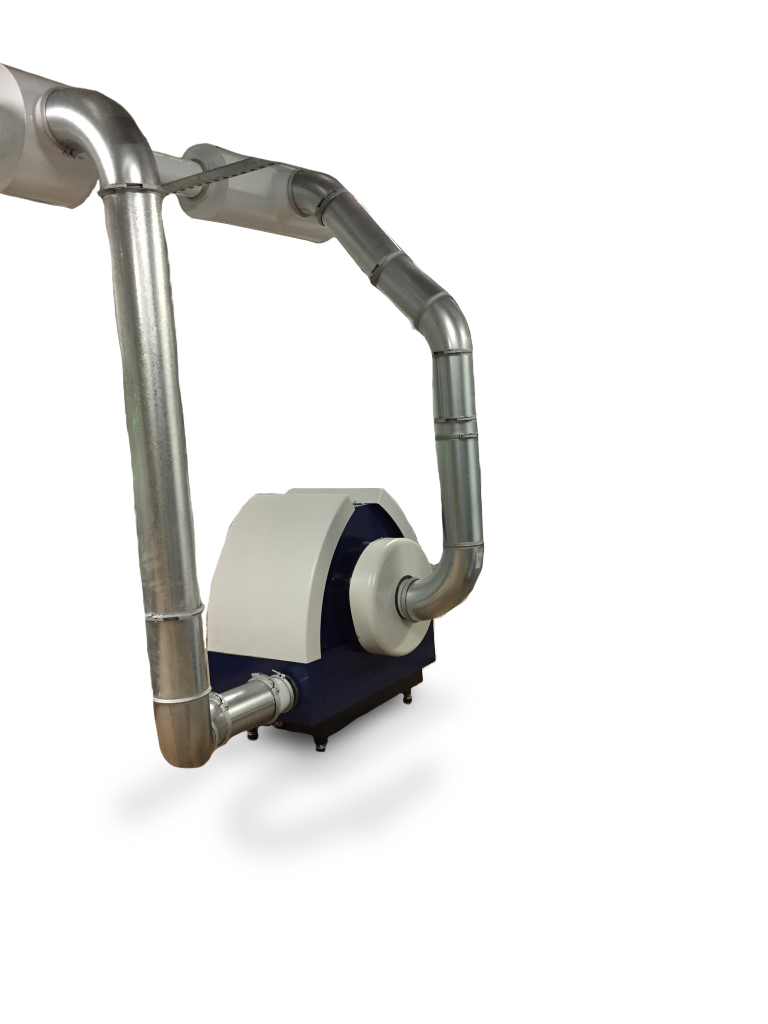

Recycling has become an integral part of our efforts to reduce waste and conserve resources. As the world’s environmental consciousness grows, so does the demand for efficient recycling processes. One key technology that plays a vital role in optimising recycling operations is pneumatic conveying allied to dust extraction systems.

Pneumatic conveying is a game-changer in the world of recycling. Its efficiency, flexibility, and ability to minimise contamination make it an essential technology for recycling facilities looking to enhance their processes.

The Recycling Challenge

Recycling is a complex process that involves the collection, sorting, and processing of various materials such as paper, plastic, glass, and metals. The challenge lies in efficiently moving these materials from one stage to another without compromising their final recycled quality. Traditional methods of material transportation, like conveyor belts and manual labour, have limitations that can hinder the recycling process.

Enter Pneumatic Conveying

Pneumatic conveying is a technology that uses air movement and pressure to transport materials through a pipework system. This method offers several advantages that make it ideal for recycling operations:

Efficiency: Pneumatic conveying systems can move a wide range of materials quickly and efficiently. This means that recycling facilities can process larger volumes of materials in less time.

Flexibility: Pneumatic conveying systems are versatile and can handle materials of different shapes, sizes, and densities. This flexibility is crucial in recycling, where materials can vary greatly.

Minimised Contamination: Pneumatic conveying systems are enclosed, reducing the risk of material cross-contamination during transportation. This is especially important when dealing with recyclables that must meet strict quality standards.

Reduced Labour Costs: By automating material transport, recycling facilities can reduce the need for manual labour, resulting in cost savings.

APS: The Experts in Pneumatic Conveying

When it comes to implementing pneumatic conveying systems for recycling, APS stands out as a trusted industry expert. With years of experience, we have demonstrated our expertise in the design and installation of Materials Handling and Dust Extraction Systems, including pneumatic conveying.

APS understands the unique challenges that recycling facilities face and customises pneumatic conveying solutions to meet specific needs. Whether it’s transporting paper, plastic, glass, or metal, we have the knowledge and technology to optimise your recycling process.

Contact us today to discuss your pneumatic conveying needs and let us help you make a positive impact on the environment.

We Consult

Understanding is key. We take the time to grasp your specific requirements, ensuring solutions tailored just for you.

We Design

With your needs as our blueprint, we craft designs that are both functional and in step with modern aesthetics.

We Install

Our team prioritises a smooth, efficient installation process, minimising disruption while focusing on optimal safety outcomes.