Case Study: Fume extraction for Harrisons Signs

We recently worked with Harrisons Signs, a bespoke signage and sign manufacturer based locally in York.

Harrisons Signs assembles cosmetic display stands for retail, a process which generates acrylic solvent fumes. The company needed something put in place to extract these fumes, to ensure the safety of their staff.

Challenges faced

Acrylic solvent fumes are harmful to inhale and therefore fall under the Control of Substances Hazardous to Health Regulations (COSHH). Under these regulations, firms are required to adequately control exposure to materials in the workplace that cause ill health.

We needed to install a fume extractor, so that the acrylic solvent fumes could be removed from the factory floor, making sure they weren’t inhaled by staff.

As well as the above, we needed to turn the project around quickly, so that Harrisons Signs could get to work on assembling the cosmetic stands.

Solution

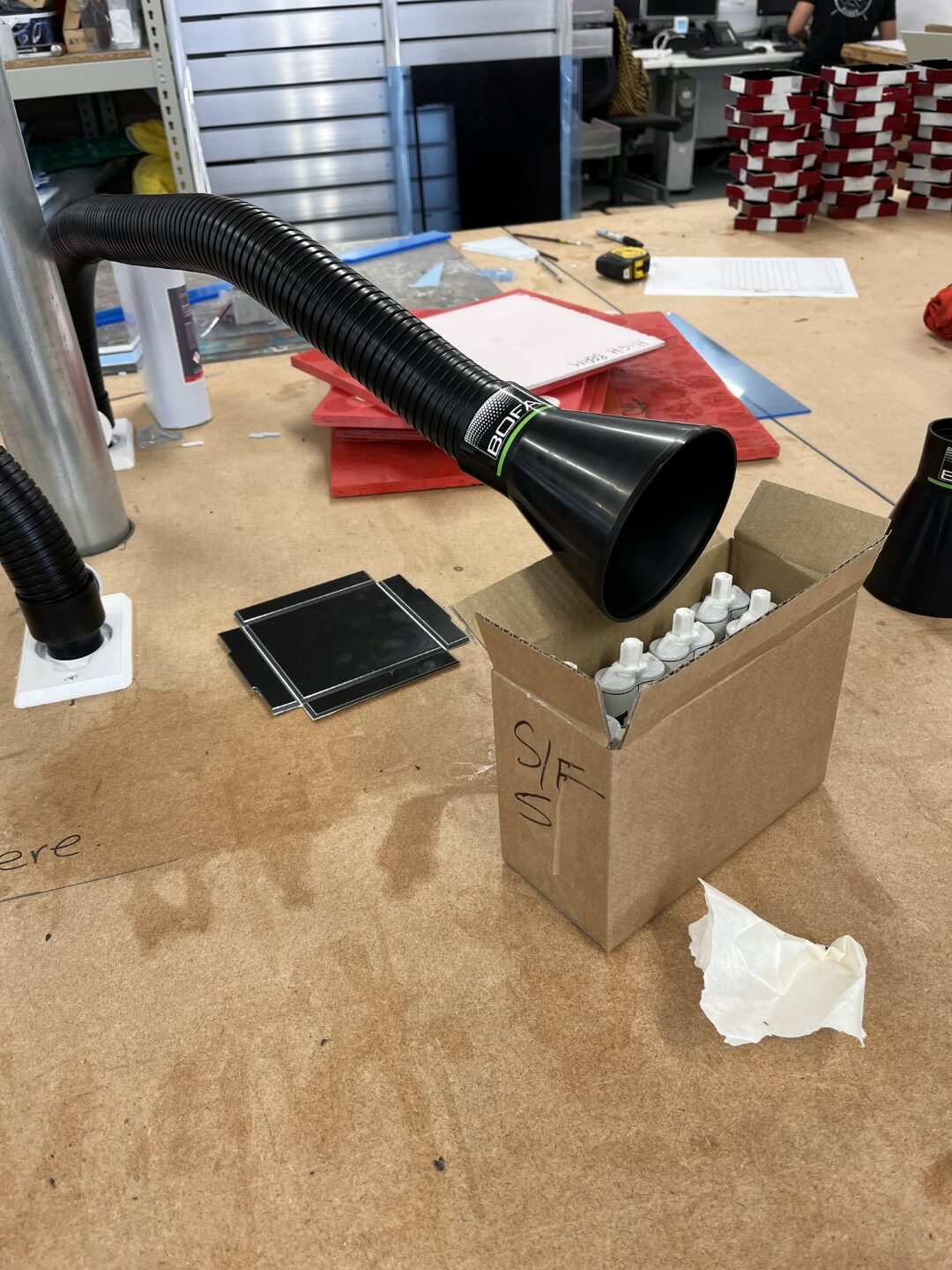

APS supplied and installed a unit from BOFA, which is a division of Donaldson, our dust collector partner.

The unit, an AD Oracle SA iQ, is a fume extractor, which is ideal for lighter use applications. The system has multiple filters, including HEPA filters which remove fine particulate, and advanced carbon filters which capture contaminants and odours.

It uses reverse air flow technology, which reduces velocity and changes air direction, causing larger particulate to fall into the filter’s drop out chamber. This decreases particulate entering the filter media, enhancing filter capture performance, and therefore extending filter life.

The Intelligent Operating System (iQ) is also included within the system and provides easy-to-access real-time data on the extractor’s functioning capability, offering multiple performance enhancements.

Benefits and outcomes

The unit installed by APS allowed Harrisons Signs to extract the harmful fumes from the factory floor, ensuring that COSHH regulations were met, and the safety of their staff was protected.

The iQ improves extraction efficiency, with individual filter status monitoring helping to flag when repairs may be needed, lowering maintenance costs and reducing downtime in the long run.

Speak to our team to learn about the fume extraction systems we can provide to you.

We Consult

Understanding is key. We take the time to grasp your specific requirements, ensuring solutions tailored just for you.

We Design

With your needs as our blueprint, we craft designs that are both functional and in step with modern aesthetics.

We Install

Our team prioritises a smooth, efficient installation process, minimising disruption while focusing on optimal safety outcomes.