Experts in Pneumatic Conveying

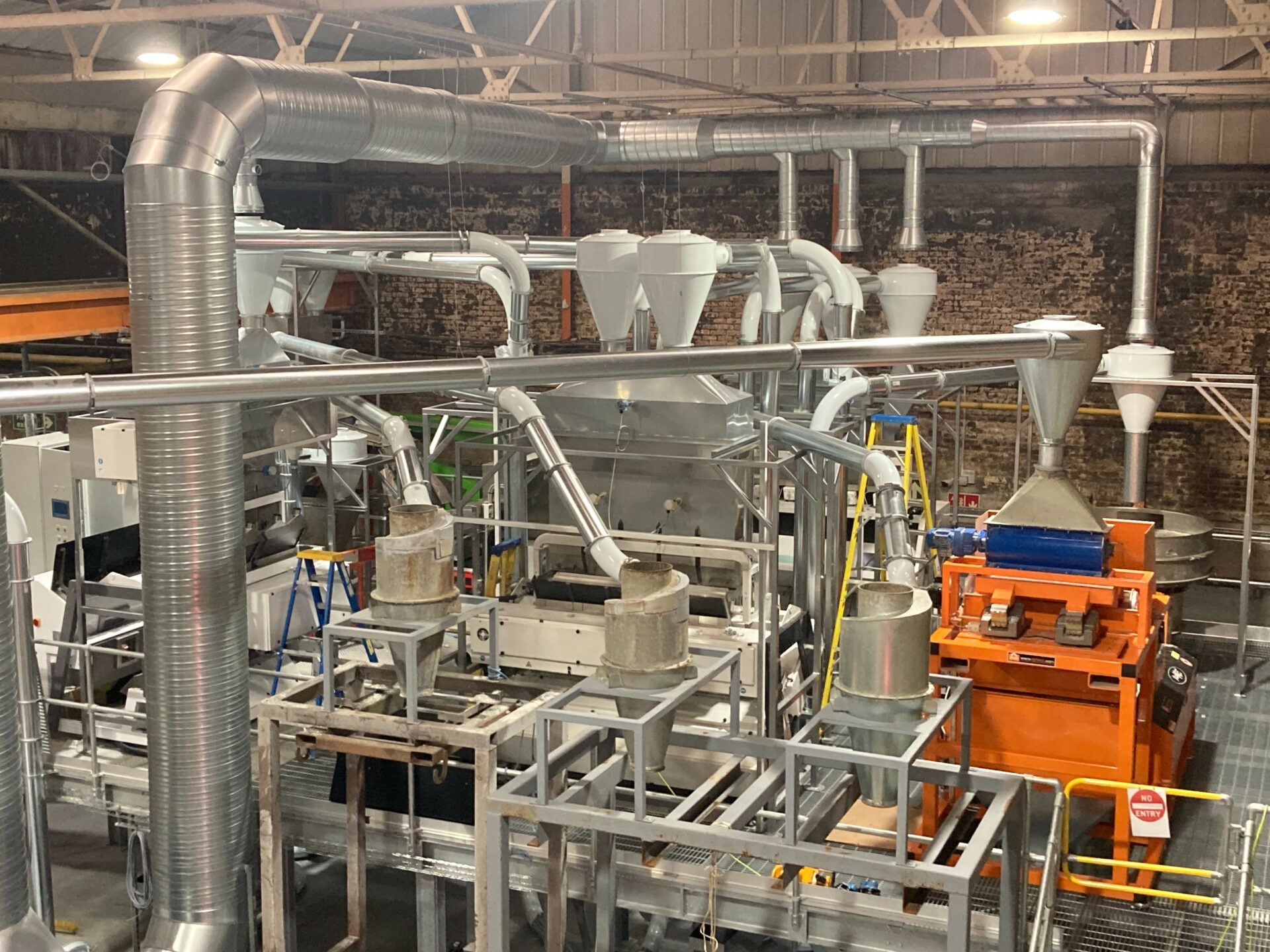

We specialise in designing, supplying, manufacturing, and installing air-conveying materials handling systems for industries like plastics, paper, food, and chemicals. With over 30 years of experience, we can help you with the safe handling of bulk materials in your production environment, working alongside you to build a solution which fits your process requirements.

APS UK specialises in providing efficient pneumatic conveying solutions for various industries, transferring granules, pellets, and moulded products. We offer both positive and negative pressure (vacuum) conveying systems, backed by years of expertise.

Our pneumatic conveying designs include the supply of handling systems for the transfer of pellets, edge trims, food and finished/waste products.

By choosing APS, you’ll be benefiting from the expertise of a UK industry leader in pneumatic conveying, helping you to minimise your wastage, reduce your costs, and stay competitive.

Our Core Services and Products

Pneumatic Handling Systems: We offer a proven and comprehensive range of pneumatic handling systems, including positive and negative pressure setups. Our modular equipment line-up comprises fan units (high and low pressure designs), venturi feeders, quick release ducting, cyclones, and rotary valves.

Specialised Equipment: We provide specialised equipment for dust filtration, grading/de-dusting, hopper loading, weighing, and vibratory feeders.

Ductwork Solutions: Our ductwork is available in various sizes (ranging from 80mm to 1000mm) and can be manufactured in either galvanised or stainless steel. Solutions are suitable for conveying food products, primary packaging, and high-grade chemicals.

Custom-Made Solutions: Dedicated manufacturing and workshop facilities to design and create custom-made equipment that precisely meets your individual requirements.

Why Choose APS UK for Pneumatic Conveying

Expertise and Reliability: With years of experience in the industry, we provide space-saving and reliable systems that reduce handling and quickly recover your initial investment.

Comprehensive Range: Our extensive range of products ensures that we can cater to all your demands in process waste handling.

Proven Performance: Count on APS for well-tested and proven pneumatic conveying solutions that are widely used across industries.

Quality Materials: We prioritise using high-grade materials to ensure the durability and efficiency of our conveying systems.

Partner with APS for your pneumatic conveying needs and experience the difference our expertise and reliable solutions make for your business.

Contact us today to discuss your requirements and explore how our solutions can enhance your operations.

Pneumatic Conveying FAQs

A: At APS, we offer a proven and comprehensive range of pneumatic handling systems, including positive and negative pressure setups. Our modular equipment line-up comprises fan units (high and low pressure designs), venturi feeders, quick release ducting, cyclones, and rotary valves.

A: Yes, APS provides bespoke pneumatic conveying solutions. We have dedicated manufacturing and workshop facilities to design and create custom-made equipment that precisely meets your individual requirements.

A: With 30 years of experience in the industry, we provide space-saving and reliable systems that reduce handling and quickly recover your initial investment. Our expert team has experience working with a wide variety of industries, meaning we can build bespoke solutions which fit your space and process requirements.